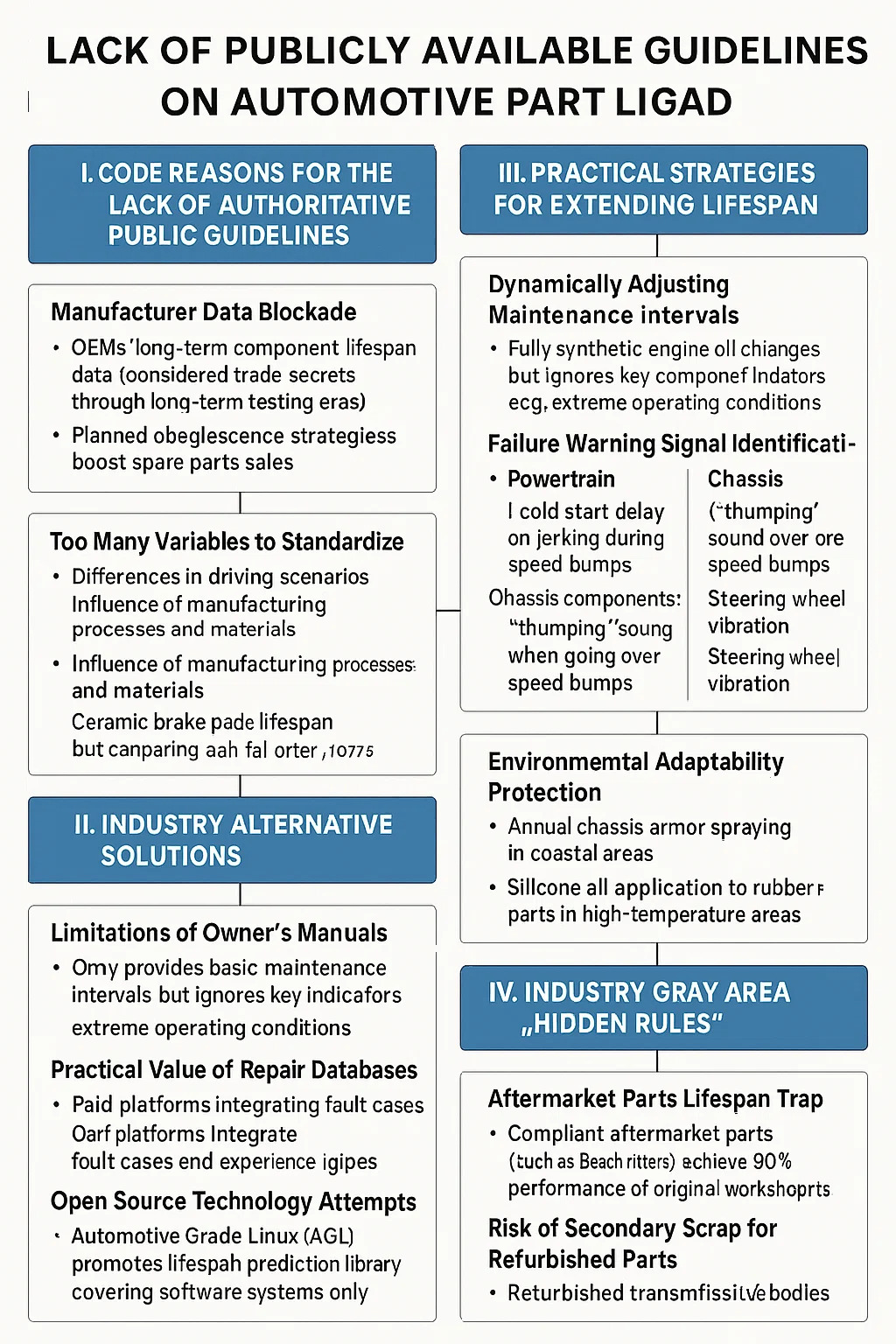

In the automotive repair industry, there is no single, publicly available guideline that comprehensively covers the lifespan of all automotive parts. This situation stems from the industry's complexity and the influence of multiple variables. The following is a key analysis of these factors:

Content

I. Core Reasons for the Lack of Authoritative Public Guidelines

• Manufacturer Data Blockade: OEMs' accumulated component lifespan data (such as timing belt breakage thresholds and bearing wear curves) through long-term testing are considered trade secrets and are not publicly disclosed.

Some automakers even employ "planned obsolescence" strategies to ensure parts fail after the warranty period, thereby boosting spare parts sales.

• Too Many Variables to Standardize:

Differences in Driving Scenarios: Engine wear is more than twice that of long-distance highway driving; chassis components rust 60% faster in areas using de-icing agents than in dry areas.

Influence of Manufacturing Processes and Materials: Ceramic brake pads have twice the lifespan of ordinary metal pads but cost three times more; most guidelines avoid such comparisons.

II. Industry Alternative Solutions

• Limitations of Owner's Manuals: Only provides basic maintenance intervals (e.g., oil changes), but ignores key component warning indicators (e.g., signs of transmission valve body wear). Does not cover recommendations for extreme operating conditions (e.g., early differential oil change after off-road driving).

• Practical Value of Repair Databases: Paid platforms (e.g., AllData) integrate fault cases, allowing users to query high-frequency fault points for specific models (e.g., turbocharger oil leaks around 100,000 km in German cars).

Experience Database of Senior Technicians: Alternator bearing lifespan in Japanese cars is generally 150,000 km, while in American cars it's only 80,000 km.

• Open Source Technology Attempts: Automotive Grade Linux (AGL) promotes the development of a lifespan prediction algorithm library, but currently only covers software systems, not hardware lifespan.

III. Practical Strategies for Extending Lifespan

• Dynamically Adjusting Maintenance Intervals: In congested traffic conditions, fully synthetic engine oil needs to be changed every 8,000 km instead of the standard 12,000 km. The inspection cycle for rubber parts in older vehicle models (engine mounts, oil seals) has been reduced to 6 months to prevent sudden breakage.

• Failure Warning Signal Identification

Powertrain: A cold start delay exceeding 3 seconds indicates fuel pump degradation; jerking during rapid acceleration indicates ignition coil aging.

Chassis Components: A "thumping" sound when going over speed bumps indicates shock absorber failure; steering wheel vibration suggests dynamic imbalance.

• Environmental Adaptability Protection

Annual chassis armor spraying in coastal areas to delay salt corrosion; silicone oil application to rubber parts in high-temperature areas to prevent hardening.

IV. Industry Gray Area "Hidden Rules"

• Aftermarket Parts Lifespan Trap

Compliant aftermarket parts (such as Bosch filters) achieve 90% of the performance of original parts, but unlabeled workshop parts have a lifespan reduced by 50%.

• Risk of Secondary Scrap for Refurbished Parts

Refurbished transmission valve bodies may reuse worn valve cores, with a secondary failure rate exceeding 40% within 3 months of installation.

English

English Español

Español