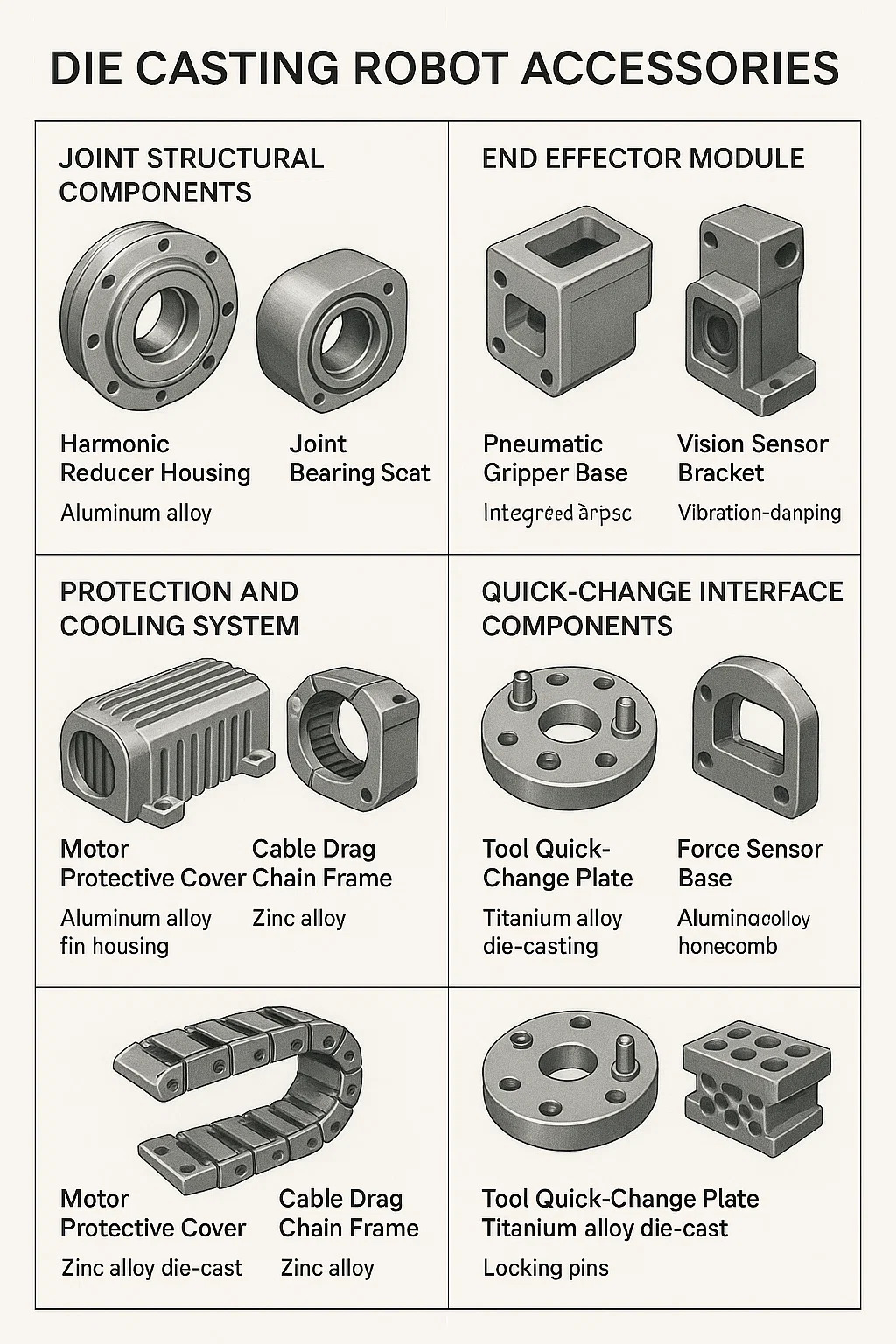

Die casting robot accessories are core metal components manufactured through a high-pressure casting process. They address the core requirements of industrial robots, including precision, lightweighting, and durability. Key applications and features are as follows:

1. Joint Structural Components - The Cornerstone of Motion Precision

Harmonic Reducer Housing:

Aluminum alloy die-casting replaces machined steel, reducing weight by 50% while maintaining micron-level geometric tolerances (ensuring ±0.02mm repeatability of the robotic arm).

Joint Bearing Seat:

Zinc alloy die-cast self-lubricating bushings are integrally molded to eliminate eccentric wear caused by assembly errors (100,000 hours of maintenance-free operation).

2. End Effector Module - The Functional Integration Hub

Pneumatic Gripper Base:

Die-cast aluminum alloy with integrated internal air passages, replacing external air tubing (for welding fixtures on automotive assembly lines).

Vision Sensor Bracket:

Magnesium alloy die-cast vibration-damping structure suppresses image blur caused by robotic arm vibration (for precision electronic component inspection).

3. Protection and Cooling System

Motor Protective Cover:

Die-cast aluminum alloy fin housing, providing both servo motor heat dissipation and metal debris isolation (for CNC machine tool loading and unloading robots).

Cable Drag Chain Frame:

Zinc alloy die-cast links, offering five times greater wear resistance than engineering plastics and resisting hydraulic oil corrosion (for robotic arms in stamping plants).

4. Quick-Change Interface Components - The Core of Flexible Production

Tool Quick-Change Plate:

Titanium alloy die-cast locking pins with tapered positioning, achieving repeatable docking accuracy ≤ 0.005mm (for switching between welding guns and grippers in 10 seconds).

Force Sensor Base:

Aluminum alloy die-cast honeycomb structure, eliminating stress interference (for precision assembly of torque feedback modules).

5. Mobile Chassis Accessories

AGV Drive Hub:

Magnesium alloy die-cast spokes, capable of withstanding 1 ton of dynamic load while reducing weight by 30% (increasing the endurance of logistics robots by 2 hours).

LiDAR Bracket:

Die-cast zinc alloy damping base, filtering ground vibration noise (for zero drift in AMR navigation positioning).

English

English Español

Español