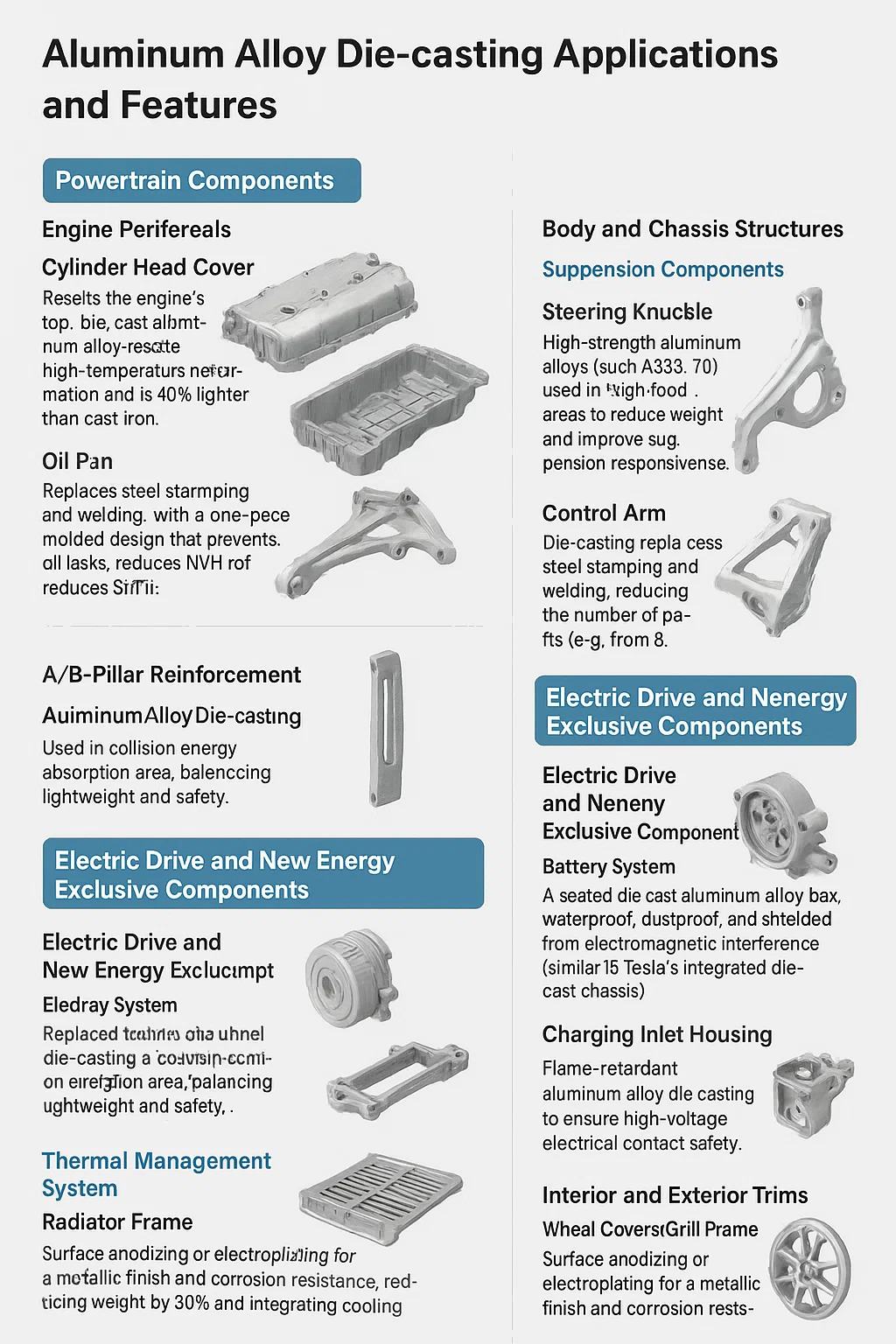

Die casting aluminum alloy automotive parts are a key driver for lightweighting and improving automotive performance. Using high-pressure casting, aluminum alloy is crafted into complex structural components, replacing traditional steel components. The following are its core applications and features:

1. Powertrain Components

Engine Peripherals:

Cylinder Head Cover: Seals the engine's top. Die-cast aluminum alloy resists high-temperature deformation and is 40% lighter than cast iron.

Oil Pan: Replaces steel stamping and welding, with a one-piece molded design that prevents oil leaks and reduces NVH (noise, vibration, and harshness).

Transmission System:

Valve Body/Clutch Housing: Internal oil passages are directly die-cast, eliminating machining costs and ensuring smooth shifting with precision.

2. Body and Chassis Structures

Suspension Components:

Steering Knuckle: High-strength aluminum alloys (such as A356-T6) are used in high-load areas to reduce weight and improve suspension responsiveness.

Control Arm: Die-casting replaces steel stamping and welding, reducing the number of parts (e.g., from five to one). Body Frame:

A/B-Pillar Reinforcement: Aluminum alloy die-casting is used in the collision energy absorption area, balancing lightweight and safety.

3. Electric Drive and New Energy Exclusive Components

Battery System:

Battery Housing: A sealed die-cast aluminum alloy box, waterproof, dustproof, and shielded from electromagnetic interference (similar to Tesla's integrated die-cast chassis).

Motor End Cover: The cooling fins are integrally molded with the housing to optimize cooling efficiency for the electric vehicle motor.

Charging System:

Charging Inlet Housing: Flame-retardant aluminum alloy die-casting to ensure high-voltage electrical contact safety.

4. Thermal Management System

Cooling Module:

Radiator Frame: A traditional steel welded component has been replaced with an aluminum alloy die-casting, reducing weight by 30% and integrating cooling ducts.

Turbocharger Intercooler Housing: A high-temperature resistant die-casting, shortening the intake air cooling path and improving engine efficiency.

5. Interior and Exterior Trims

High-End Trims:

Wheel Covers/Grill Frame: Surface anodizing or electroplating for a metallic finish and corrosion resistance. Functional Integrated Components:

Door Lock Bracket: Zinc-aluminum alloy die-casting ensures wear resistance and long-term use without loosening.

English

English Español

Español