Die casting garden tools are metal core components manufactured through a high-pressure casting process. This gives them high strength, lightweight, and weather resistance, significantly improving durability and user experience. The following are their core applications and features:

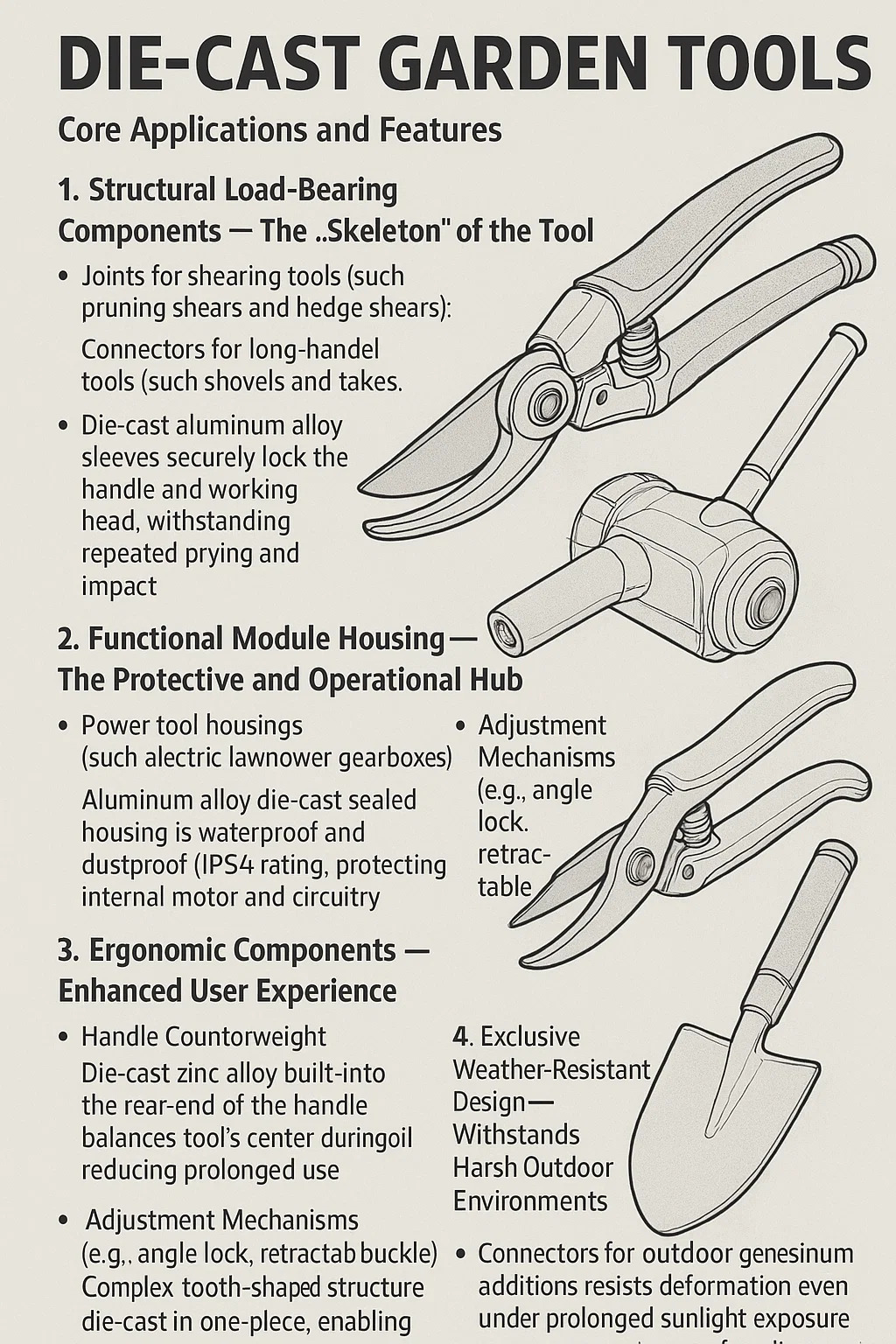

1. Structural load-bearing components—the "skeleton" of the tool.

Joints for shearing tools (such as pruning shears and hedge shears):

Zinc-aluminum alloy die-casting replaces traditional riveted steel blades, eliminating the risk of loosening and ensuring precise blade engagement.

Connectors for long-handled tools (such as shovels and rakes):

Die-cast aluminum alloy sleeves securely lock the handle and working head, withstanding repeated prying and impact.

2. Functional module housing—the protective and operational hub.

Power tool housings (such as electric lawn mower gearboxes):

Aluminum alloy die-cast sealed housing is waterproof and dustproof (IP54 rating), protecting the internal motor and circuitry.

Sprayer pump body:

Corrosion-resistant zinc alloy die-cast pump chamber resists corrosion from pesticides and fertilizers, preventing leakage.

3. Ergonomic Components - Enhanced User Experience

Handle Counterweight:

Die-cast zinc alloy built into the rear end of the handle balances the tool's center of gravity, reducing fatigue during prolonged use.

Adjustment Mechanisms (e.g., angle lock, retractable buckle):

Complex tooth-shaped structure die-cast in one piece, enabling precise one-handed adjustment (e.g., angle adjuster for garden shears).

4. Exclusive Weather-Resistant Design - Withstands Harsh Outdoor Environments

Surface Treatment:

Anodized aluminum alloy rust-resistant layer resists corrosion from rain and soil (e.g., where the shovel head contacts the soil).

Material Anti-Aging:

Aluminum alloy with copper/magnesium additions resists deformation even under prolonged sunlight exposure (e.g., connectors for outdoor fixed plant stands).

Why is die-casting technology so popular with gardening tools?

Lightweight Revolution: Aluminum alloy die-cast pruning shears are 50% lighter than steel, making them easier for female users to operate.

Extended Lifespan: Die-cast gearboxes offer over three times the impact resistance of plastic-shelled power tools.

Cost Control: In mass production, die-cast composite structural components are less expensive than CNC machining and assembly.

Comparison of Typical Tool Applications

| Traditional Pain Points | Die-Casting Solution | User Value |

| Steel tool joints rust and seize | Zinc alloy die-cast joint + self-lubricating bushing | Maintenance-free smooth operation |

| Plastic sprayer pump cracks/leaks | Monolithic zinc alloy chemical-resistant pump body | 10-year leak-proof durability |

| Wooden shovel handles loosen at connection | Aluminum die-cast locking sleeve | Lifetime anti-detachment reliability |

English

English Español

Español